This article was originally published by Michael Coates on Clean Fleet Report, a publication that gives its readers the information they need to move to cars and trucks with best fuel economy, including electric cars, fuel cells, plug-in hybrids, hybrids and advanced diesel and gasoline engines.

According to dozens of automotive story headlines, the internal combustion engine, running on gasoline or diesel, is dead or dying as customers, auto companies, and investors flock to electric powertrains. Even heavy-duty trucks running on massive diesel engines, which were expected to be the last on-road holdouts, have been mandated to turn completely to zero emissions in by the state of California starting in 2045.

While 2045 may still be more than two decades away, emissions advances in internal combustion engines (ICE) are continuing. A new technology may take the already quite clean (especially compared with engines of just a little more than a decade ago) engines to a level that reduces smog-producing emissions while increasing fuel economy and yet not losing any performance. The technology study was announced last month by Cummins, the largest heavy-duty engine manufacturer, and Tula Technology, a technology innovator in Silicon Valley that has become a supplier to OEMs.

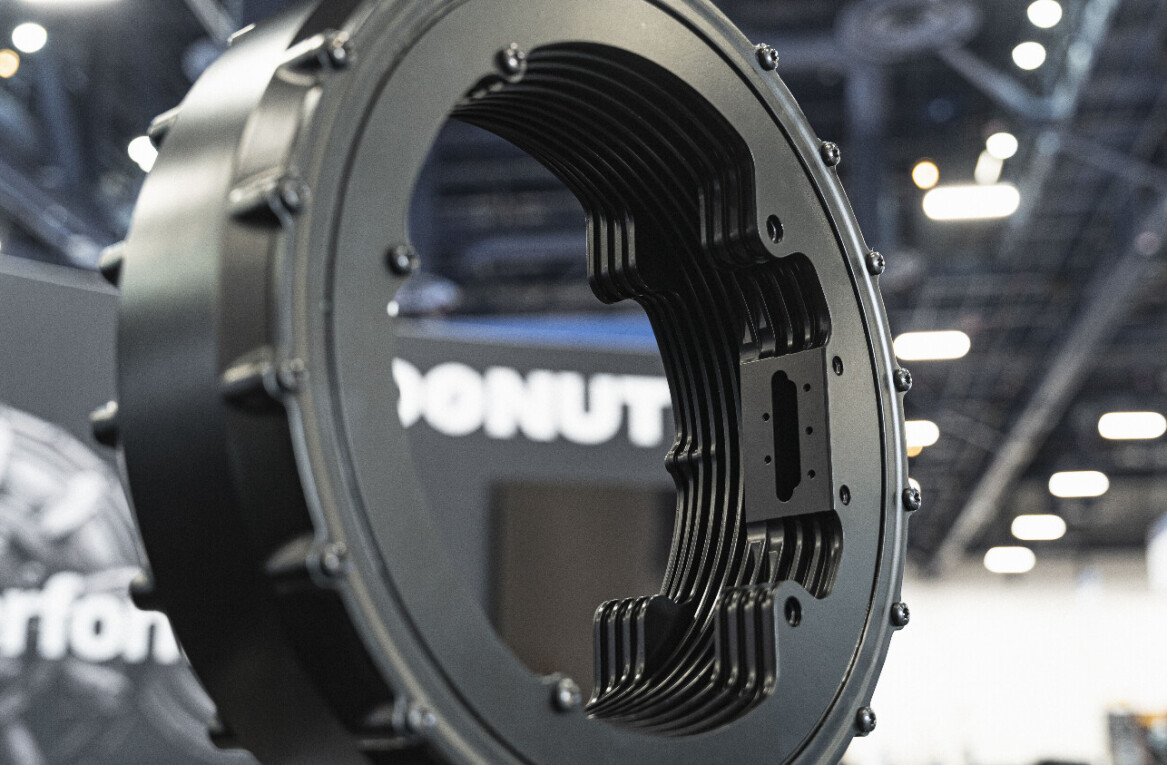

According to the study, adding Tula’s diesel Dynamic Skip Fire (dDSF) technology to a current Cummins engine resulted in a 74% reduction in NOx and a 5% reduction in CO2 compared to the base engine. Running dDSF also saved 20% in fuel. The engine used for the test was a Cummins X15, a current state-of-the-art diesel engine found in many Class 8 trucks. DSF is an advanced cylinder deactivation system that micromanages each of the engine’s cylinders to balance torque demands while optimizing fuel economy.

The test procedures

The test replicated not only the usual test cycles used to certify engine emissions, but also ones designed to capture emissions in difficult low-speed, low-load situations, where diesel engines typically have higher emissions. Tula said the tests included dyno testing as well as on-road testing. Testing is ongoing.

“Our mission at Cummins is to make people’s lives better by powering a more prosperous world, and we accomplish this through innovation,” said Lisa Farrell, director, Accelerated Technology Center for Cummins Inc. “Tula’s dDSF technology provides significant benefits to reducing NOx and CO2 emissions under low-load vehicle operation, which will aid our efforts to produce more reliable, more powerful engines while meeting our environmental goals.”

Cummins, evolving into a propulsion-system company from its history as an diesel engine manufacturer, has not only embraced improvements to conventional engines, but also is developing battery electric and fuel cell electric powertrains as well as also remaining the major heavy-duty natural gas engine provider through its Cummins Westport operation. Its diesel engines remain mainstays at all of the major North American OEMs.

Attacking the NOx

“NOx standards are becoming progressively more stringent for diesel engines, and meeting those standards is increasingly challenging, even for a class-leading, efficient engine like the Cummins X15 HD,” said Scott Bailey, CEO of Tula Technology. “Our dDSF is a powerful and unique technology that enables original equipment manufacturers to significantly reduce NOx emissions that contribute to smog while simultaneously reducing fuel consumption and greenhouse gas production. We appreciate the opportunity to work with Cummins to demonstrate the capability of our technology.”

Tula has a track record with gasoline engine applications of the DSF technology. It has worked since 2018 with General Motors to incorporate DSF into more than a million of the company’s V8-engine models, including the Cadillac Escalade, Chevrolet Silverado and Suburban, and GMC Sierra and Yukon. The company estimates that the use of DSF has prevented up to one million tons of CO2 from being emitted by these vehicles annually because of fuel economy improvements.

Like Cummins, Tula is also looking beyond ICE, applying its efficiency technology to electric motors to increase range while using less energy. According to a recent paper by Tula, it has simulated efficiency improvements of 2.5% on the Worldwide Harmonized Light Vehicle Test Procedure (WLTP) cycle for EVs. The software upgrade doesn’t require any hardware changes to the motor or vehicle. It also reduces the amount of rare earth materials needed.

The test participants didn’t speculate on when the dDSF might be available on production engines, but the U.S. Environmental Protection Agency is beginning looking at more stringent NOx limits for future heavy-duty diesel engines and the state of California already has a regulation that will begin in 2024 dropping the allowable NOx limit by 75% while also instituting testing on the low-load cycles that the dDSF technology is aimed at. That standard is scheduled to drop further in 2027.

Do EVs excite your electrons? Do ebikes get your wheels spinning? Do self-driving cars get you all charged up?

Then you need the weekly SHIFT newsletter in your life. Click here to sign up.

Get the TNW newsletter

Get the most important tech news in your inbox each week.