Annual car sales are unlikely to reach pre-COVID-19 levels anytime soon. In fact, experts say that the rate of recovery is forecasted to be a result of a slowdown in internal combustion engine (ICE) vehicles, with electric vehicles gaining a positive trajectory during the pandemic recovery period and beyond. According to a recent Deloitte study, EVs are likely to secure 32% of the global market share for new car sales by 2030.

More electric vehicles! Sounds great for the environment, right? Yes, but electric car manufacturers have to tread carefully. More EVs means more batteries, and it’s essential that companies source the raw materials needed for batters ethically, particularly cobalt.

Tracing cobalt on the blockchain

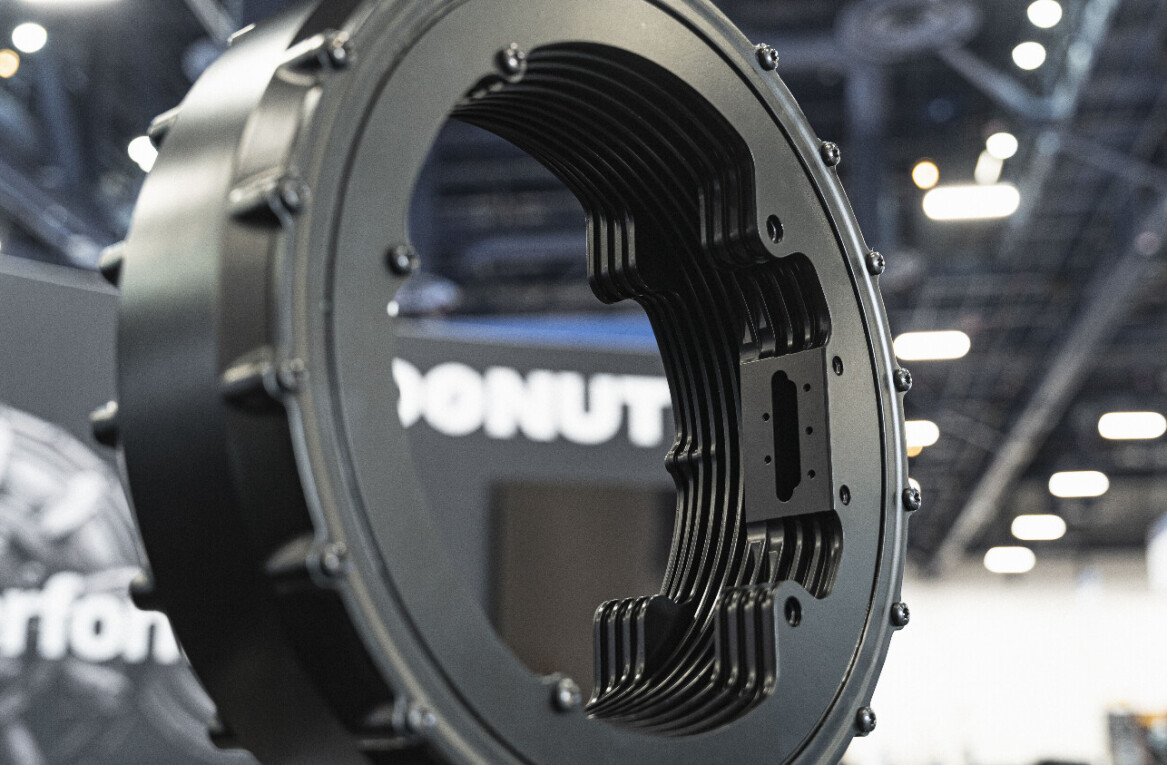

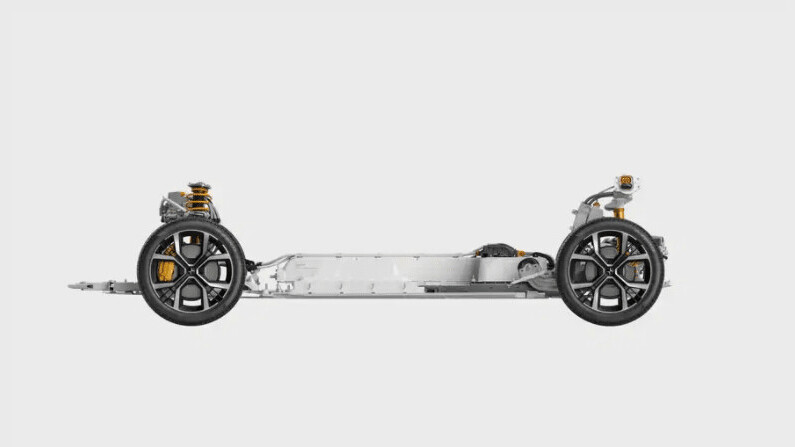

Polestar, a recent EV launch, was the first car to announce the use of blockchain to trace cobalt in its batteries, according to Polestar’s Head of Sustainability Frederika Klarén. You might have heard about blockchain in the context of cryptocurrency, like Bitcoin. But blockchain’s uses can extend far beyond digital currency and into the realm of sustainable supply chain management.

Polestar, a brand that advocates for transparency and accountability in the electric vehicle manufacturing industry, believes in the potential of blockchain technology to validate the ethical production of its batteries.

Blockchain records a digital register of transactions within a supply chain that cannot be altered. This transparent traceability means that the sources of the materials, and the methods by which they’re extracted, processed, and transported can be regulated. It’s truly setting the precedent for sustainable supply chain management.

Improving mining conditions

Cobalt is an important resource for battery production. The element helps keep lithium batteries cool during charging and discharging, but obtaining cobalt often presents terrible conditions for miners, particularly in the Republic of Congo.

Earlier this year, reporters uncovered how an army of 35,000 children was mining cobalt in toxic conditions, sparking debates between consumers and manufacturers of electronic products focused on finding a way to improve the situation.

“It was important to us to start with cobalt when piloting this innovative technology. We need many tools to fight the cobalt supply chain risks relating to child- and human rights violations. Supporting communities through programs such as Better Mining, increasing the use of recycled content, and implementing responsible sourcing practices are some of them. And now we can also add blockchain to the list,” said Klarén.

Last year, Polestar worked out an agreement with its two battery suppliers, CATL from China and LG Chem from South Korea, to ensure the cobalt used in its batteries is globally traceable using blockchain technology. Polestar’s blockchain for tracking the life cycle of its cobalt will collect data on the origin, size, weight, chain of custody, and information showing adherence to OECD supply chain guidelines.

Ambitious goals

By guaranteeing that the information in the transaction records cannot be changed without detection, the process improves the scrutiny of the supply chain and demonstrates that vehicle manufacturers can and should only rely on materials that are sourced responsibly and ethically.

Polestar’s sustainability goals are ambitious. In the future, the company hopes to gain more accurate results regarding the carbon footprint and ethical considerations of materials included in the production of its batteries by obtaining data directly from the suppliers. Currently, Polestar is using data gathered from the International Material Data System, a dataset that contains information on material compositions of vehicle components.

“Given the relatively large carbon footprint from the battery, increased collaboration with battery suppliers should be prioritized,” authors of the LCA wrote.

Ambitious goals, yes. But in order to see sustainable progress in the electric vehicle industry in particular, and the automotive industry in general, companies need to make transparency and sustainability a priority.

Get the TNW newsletter

Get the most important tech news in your inbox each week.