Not so long ago, trying to integrate 3D printing into your small business took a huge hunk of time and cash. Not only were printers big and expensive, they also required skilled technicians to make prototypes work properly. The explosion of the Maker movement has changed that by bring 3D printing to the hobbyist set.

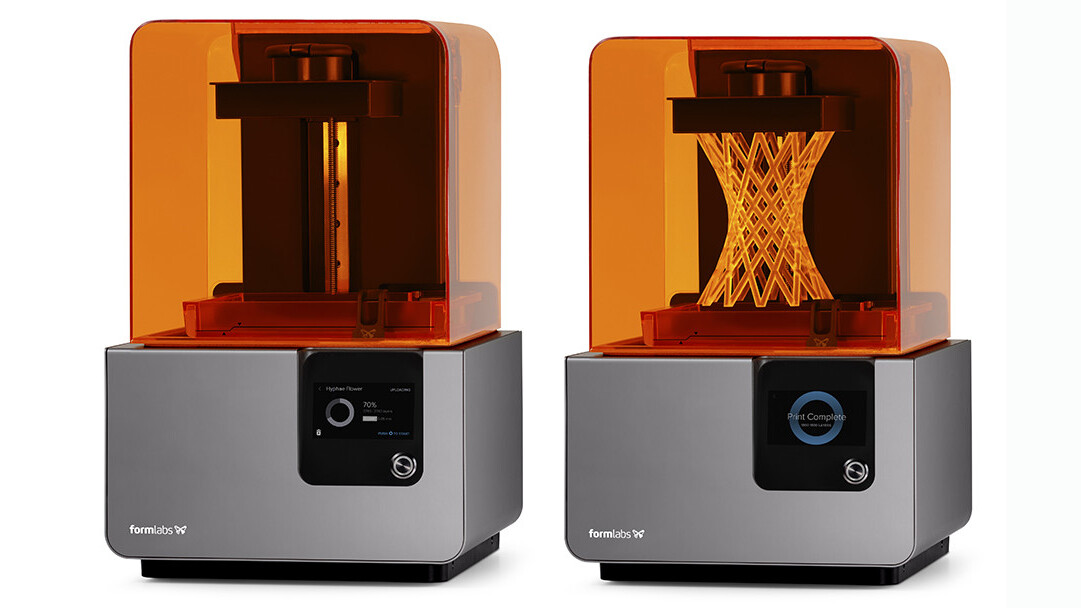

Formlabs now seeks to bridge the gap between hobbyist and industrial use with a brand new high-resolution, desktop stereolithography (SLA) 3D printer — the Form 2, launching today — aimed squarely at designers, engineers and a host of creative professionals.

Form 2 is actually the third iteration of the Formlabs printer, and has been rebuilt from the ground up. New “prints” are more than 40 percent bigger and derived from a more powerful laser that yields better resolution.

New connectivity options facilitate printing over Wi-Fi, alongside custom notifications and mobile alerts. A new dashboard lets users monitor print progress across multiple printers on the desktop or via mobile devices or tablets.

“The dirty secret about 3D printing is that it fails a lot because there are so many variables in making a project,” said Formlabs co-founder Max Lobovsky, who led TNW through an in-person demo of the new printer.

“What we tried to do when we designed this machine was to account for all the variables that would cause failure. Instead of adding all these fantastic features with cameras and crazy sound, we really tried to make a reliable machine because that’s what this movement needs.”

The machine’s small footprint and attractive exterior are a natural fit for designer studios, engineering shops, jewelers and anywhere precise prototypes are needed.

“If you make a machine that’s extremely reliable with a small footprint that you can put in a designers studio or an engineering shop, you can do things that will change the world because you give them tools that they never had before to make things that never existed before.”

A new print process featuring a sliding peel mechanism, wiper and heated resin tank facilitates printing large, solid parts with intricate details. An automated resin system with new cartridges now automatically refills the resin tank during the printing process. A full color touchscreen manages print queues and shows print status.

The printer uses standard or functional resins where each has a purpose depending on what you are printing. They are proprietary and custom designed to be used with the printer.

With its one-click interface, the Form 2 could not be easier to use, and that is by design. “It’s like the Mac; you don’t have to think about it. When it’s printing, it’s printing,” said Lobovsky. “We envision that teams will be working with it and that people will get text messages when the project is done.”

The Form 2 is available for purchase today for $3,499 and includes Formlabs’ PreForm software, one liter of resin for printing and a finish kit for post processing. The printer ships within a few weeks.

Said Lobovsky, “This is the Macintosh moment of the 3D printing world where we put a new interface on it and make it really easy — and because you’ve done that, you’ll be surprised at all the things that people can do with it.”

➤ Formlabs

Get the TNW newsletter

Get the most important tech news in your inbox each week.