I think we can all agree that the evolution of 3D printing technology thus far has been stunning. But I wanted to know what specific ways entrepreneurs are actually looking to use the technology in business, and why — so I asked a panel of nine founders the following:

As an entrepreneur, what’s most exciting to you about 3D printing? Where do you see it being utilized most in the near term?

Their most compelling responses are below.

1. Fewer manufactured goods

1. Fewer manufactured goods

“Things” will no longer be manufactured and shipped to customers. Instead, you’ll purchase designs for everything from glasses to housing, and the input costs of having them printed on site will be cheaper than the current supply-chain process we have today.

Once it becomes more cost-efficient to build this way (and it will) you’ll have an ‘app store’ of objects you can download and print out at your leisure. I believe this will be the biggest revolution since the Internet itself.

![]() 2. Printable knickknacks

2. Printable knickknacks

I love the idea of having a 3D printer to build all the little knickknacks in my life, from the screw that I lost in my IKEA coffee table to an extra pair of earbuds for running. I see 3D printers being utilized as personal Lowes and Home Depot stores in our homes.

![]() 3. Cheaper samples

3. Cheaper samples

One of the most expensive aspects of the fashion world is creating samples before production. Getting one sample made can range anywhere from $200 to $400.

I love the idea that 3D printers can help make that process easier for young designers, especially as more wearable materials are sourced for 3D printing.

![]() 4. Reduced manufacturing costs

4. Reduced manufacturing costs

What’s most exciting about 3D printing is that it will significantly reduce manufacturing costs for aspiring entrepreneurs. As it begins to gain more of a foothold, you’ll see it take the place of the manufacturing segment of a startup.

– Andrew Schrage, Money Crashers Personal Finance

![]() 5. Testable ideas

5. Testable ideas

Manufacturing needs have always been a limiting factor for small businesses. Due to high minimum quantities, the starting cost is often prohibitive. With the “Lean Startup” movement underway, tech startups think about testing a minimum viable product before they try to build an “A+” product.

Physical product companies can test ideas with 3D printing before investing the time and money needed to for full-blown production. More ideas will be tested, and more good companies will be started thanks to the proliferation of this technology.

– Aaron Schwartz, Modify Watches

![]() 6. Printable necessities

6. Printable necessities

The potential of 3D printing seems endless. I’ve seen and heard of small houses being built for the less fortunate, as well as medicine and even food being produced from the technology. It’s fascinating how fast these things can be made.

It seems that anything you can see or feel can somehow be printed! In the near future, I see small accessories such as mobile phone cases and jewellery being produced.

– Shahzil (Shaz) Amin, Blue Track Media, LLC

![]() 7. At-home startups

7. At-home startups

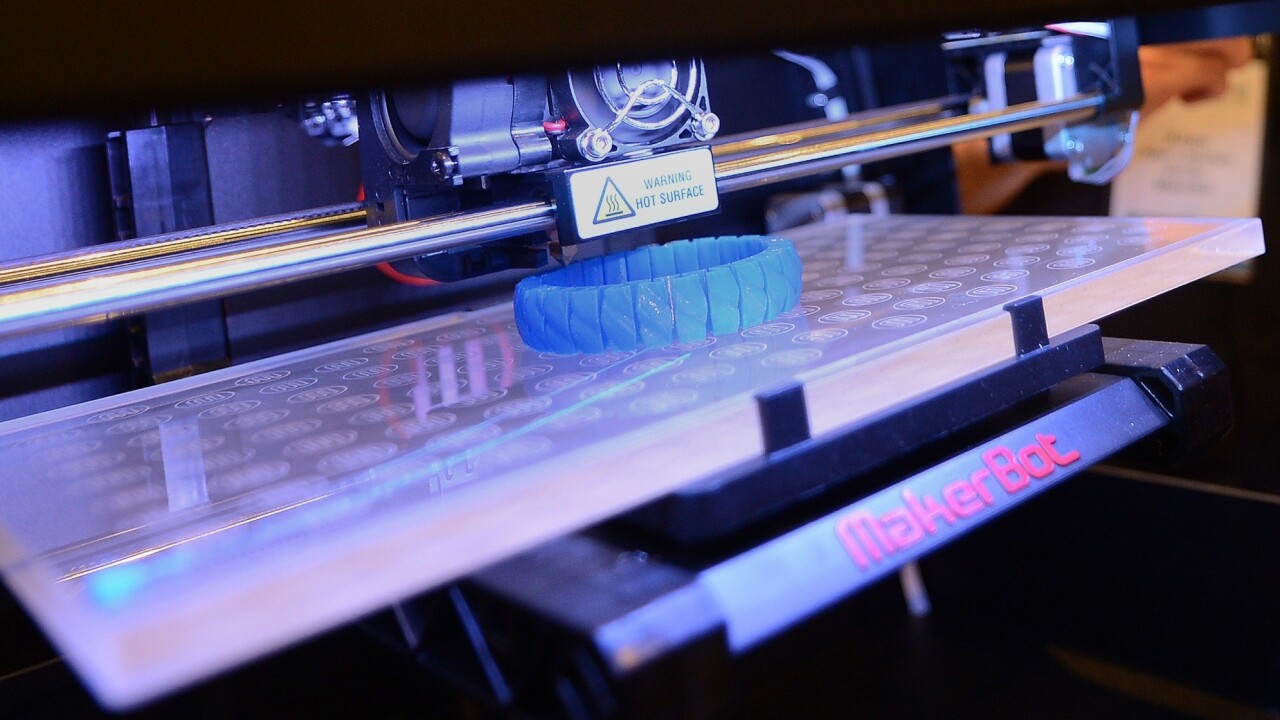

As an entrepreneur, I’m very excited by the newly streamlined ability to scan and reproduce 3D objects. This scanning capacity was unveiled at the 2013 SXSW Interactive Festival in Austin as MakerBot Industries demonstrated its desktop “digitizer” device. Using this device, the possibilities are nearly endless, but I am especially excited by the opportunities of scale.

Prior to 3D printing, there was no middle ground for manufacturing between tiny artisan quantities and large mass production. Now, I can create a prototype, scan it and begin production in my home.

– Jay Wu, Best Drug Rehabilitation

![]() 8. Increased efficiency

8. Increased efficiency

I’m really excited to see what 3D printing is going to do for design and manufacturing. People are going to be able to prototype 10 times faster with optimal use of space and materials, which greatly increases their efficiency.

I think we’ll see more ideas become actual products as 3D printing becomes more accessible.

9. Old parts for machines

9. Old parts for machines

As a manufacturer, the most immediate impact will be in replacing parts for machines that are no longer being produced. We have machines built by a manufacturer that went out of business, and replacing the part will cost more than the original machine.

– Sam Saxton, Salter Spiral Stair and Mylen Stairs

The Young Entrepreneur Council (YEC) is an invite-only organization comprised of the world’s most promising young entrepreneurs. In partnership with Citi, the YEC recently launched #StartupLab, a free virtual mentorship program that helps millions of entrepreneurs start and grow businesses via live video chats, an expert content library and email lessons.

Image credit: EMMANUEL DUNAND/AFP/Getty Images

Get the TNW newsletter

Get the most important tech news in your inbox each week.