If you play around to make things in a workshop, you might’ve used a laser cutter to create things at one point. Usually, you would use different materials by trial and error method to reach the desired shape and function.

However, researchers from MIT are making this process safer by using machine learning. The team from MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) has come up with a technology called SensiCut, a material sensing platform for laser cutters that warns you of potentially harmful materials.

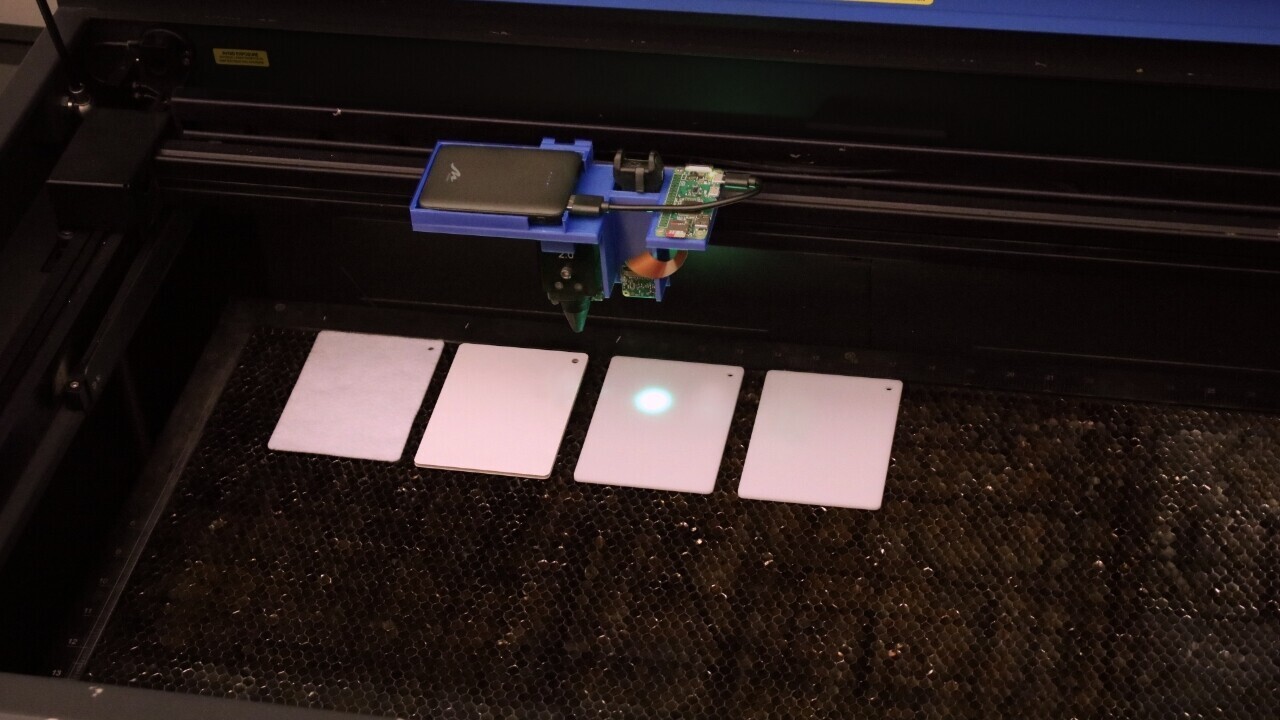

The tool consists of low-cost hardware components such as a Raspberry Pi Zero microprocessor board hosted in a 3D printed board. The module is then attached to the laser cutter and the neural network of the tool identifies various materials based on the speckled image of a material’s surface microstructure.

You can watch SensiCut in action below, where a researcher is getting suggestions for different materials while making a face shield.

To train SensiCut’s algorithm, the team used more than 38,000 images of 30 material types. The tool can also guide you to use different speeds and cut settings for different materials.

Mustafa Doga Dogan, PhD candidate at MIT CSAIL, said that this tool reduces the overall waste of materials in the workshop:

By augmenting standard laser cutters with lensless image sensors, we can easily identify visually similar materials commonly found in workshops and reduce overall waste. We do this by leveraging a material’s micron-level surface structure, which is a unique characteristic even when visually similar to another type. Without that, you’d likely have to make an educated guess on the correct material name from a large database.

The team believes that the tool could be used for 3D printers in the future too.

Get the TNW newsletter

Get the most important tech news in your inbox each week.